Limacon Production Monitor

What is Limacon Production Monitor?

Limacon Production Monitor is an ambitious, self-funded project aimed at replicating the functionality of the Vorne XL Productivity Appliance (Vorne XL) to develop a similar product and codebase.

The Vorne XL is a well-established, successful, and expertly implemented production monitoring and performance management system. It automates factory data collection, provides real-time and historical visibility into manufacturing processes with over 140 metrics and customizable reports, and enables data-driven decision-making to enhance efficiency and address production issues.

The development of Limacon Production Monitor was undertaken with the potential goal of bringing an OEE (Overall Equipment Effectiveness) software product to market or providing technology to a partner company specializing in OEE or reliability engineering consulting.

Development Process

The idea for this project emerged in 2022, leading to extensive research and study of publicly available Vorne product manuals. A design was created to replicate most of the XL’s functionality.

Development began in January 2024 as a part-time effort, transitioning into full-time work from April to December 2024. Over this period, the core production monitoring and OEE calculation functionality were implemented, alongside Docker deployment to Debian 11. Additionally, an extensive suite of testing assets was developed, incorporating a detailed production line simulation capable of generating test data. This data could be either rapidly processed through the production monitor or played back in real time to replicate the operator’s experience.

Technologies, Tools and Features

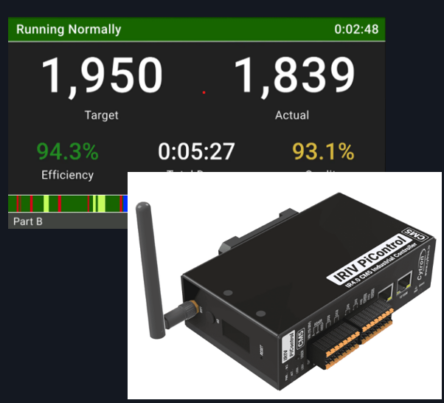

The Limacon Production Monitor is an “appliance” (a preconfigured combination of hardware and software) with the following capabilities:

- Collects counts from factory equipment via digital I/O

- Accepts operator inputs from a barcode scanner for run control and failure reason entry

- Displays real-time production line status (running or stopped) on an HDMI monitor

- Builds an SQL database of production run and line event data for historical queries

The technology stack includes:

- Operating System & Deployment: Debian 11, Docker Containers, Docker Compose

- Programming Languages & Frameworks: C# with ASP.Net Core, SQLite, VueJS and Python

The testing assets feature:

- A detailed production line simulation with realistic scheduling parameters

- A real-time simulation of digital I/O signals coming off of production hardware

The target hardware for the product is the IRIV PiControl IR4.0 Industrial Controller provided by Cytron Marketplace. The real-time line simulator is designed for the IRIV IO Controller – IR4.0 Industrial I/O Controller, also from Cytron.

Outcomes

The system has undergone a significant amount of testing and produces accurate OEE values and many other production metrics. It currently lacks the detailed and customizable reporting features that the Vorne product includes.

The Cytron hardware has proven to be reliable, cost-effective and easy to work with.

I have learned and polished quite a few new skills during the process.

I would consider opportunities to collaborate on the further development of this product.